Technology

Toyota has been working to achieve a hydrogen-based society through sales of the "MIRAI" FCEV and "SORA" FC buses, sales of FC systems to FC product vendors, and actions such as providing FC-related patents for free. Through these activities, Toyota came to realize that there is demand from many vendors in diverse industries for an FC system that is easy to adapt to their own products.

Responding to these needs, Toyota will provide the highly advanced FC system and tank of MIRAI in a form that is easy to use.

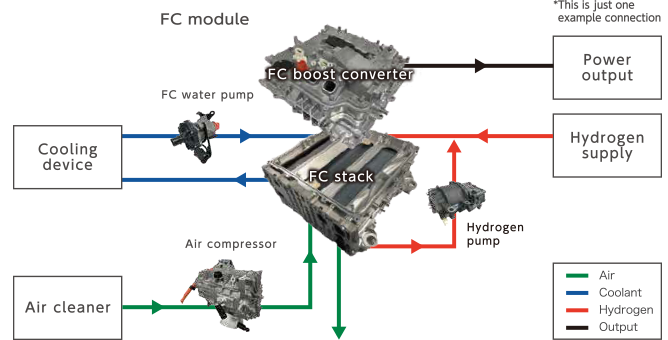

FC module

Highly versatile product

lineup and high installability

Connect directly to existing electrical systems

The wide voltage range and dedicated boost converter allows it to connect directly to existing electrical systems.

Adaptable to a wide range of output levels and installation space

Four module variations are provided for different uses. They can be combined flexibly adapting to the output level and amount of installation space available.

Modular structure ensures easy installation

Modularization facilitates the installation design and connections between components. Consolidating the connection locations provides higher installability.

Superior safety reliability, and a confidence-inspiring support framework

Safety measures cultivated through the development of FCEVs and HEVs.

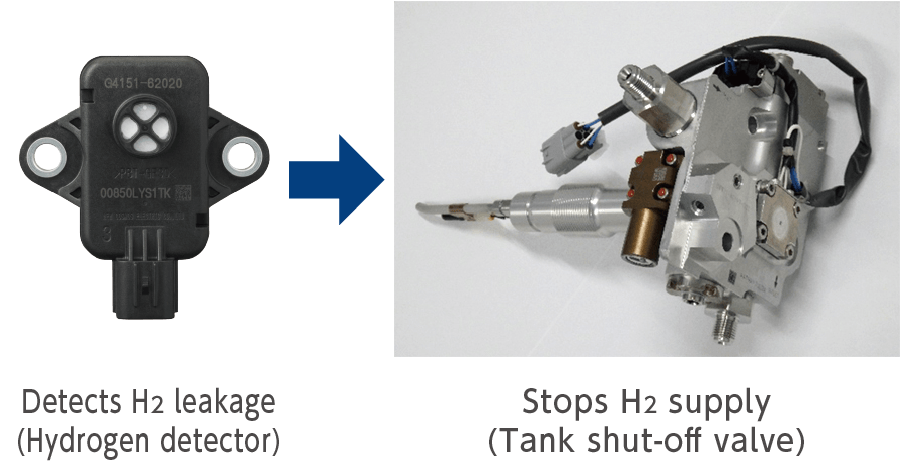

Leak resistant, detects and stops any leaks that occur

Benefits from the hydrogen and high-voltage safety measures cultivated through the development of electrified vehicles such as FCEVs and HEVs.

Adapted to a broad range of environments

Adapted to a broad range of environments, including operating at high and low temperatures, high altitudes, and when subjected to vibration.

Engineering support for optimal layout & design

Toyota's engineering team provides support for determining the optimal layout and design based on customer needs for fuel efficiency, lifetime and TCO.

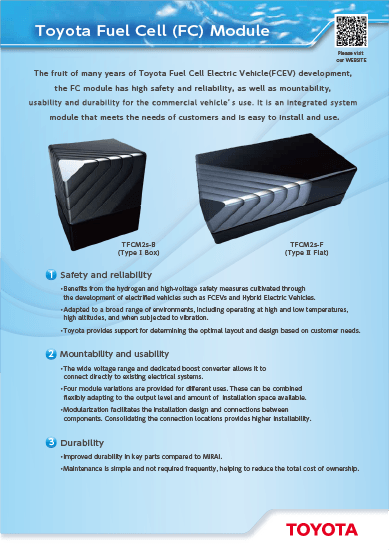

FC module overview

| TFCM2s-B (Type I Box) |

TFCM2s-F (Type II Flat) |

|

|---|---|---|

| Size | L 890 / W 630 / H 697 mm | L 1270 / W 630 / H 410 mm |

| Mass | Approx. 235 kg | Approx. 240 kg |

| Rated Power | 65 kW and 85 kW 2 types | 65 kW and 85 kW 2 types |

| Voltage | 400 to 750 V | |

Includes development targets

Superior basic performance

World-class, top-level output density per unit volume.

Eliminated the humidifier by circulating the water generated during power generation inside the FC stack, enabling the new module to achieve a world-leading output density per unit volume.

Helping to reduce the total cost of operation

Maintenance is simple and not required frequently, helping to reduce the total cost of operation from procurement until disposal.

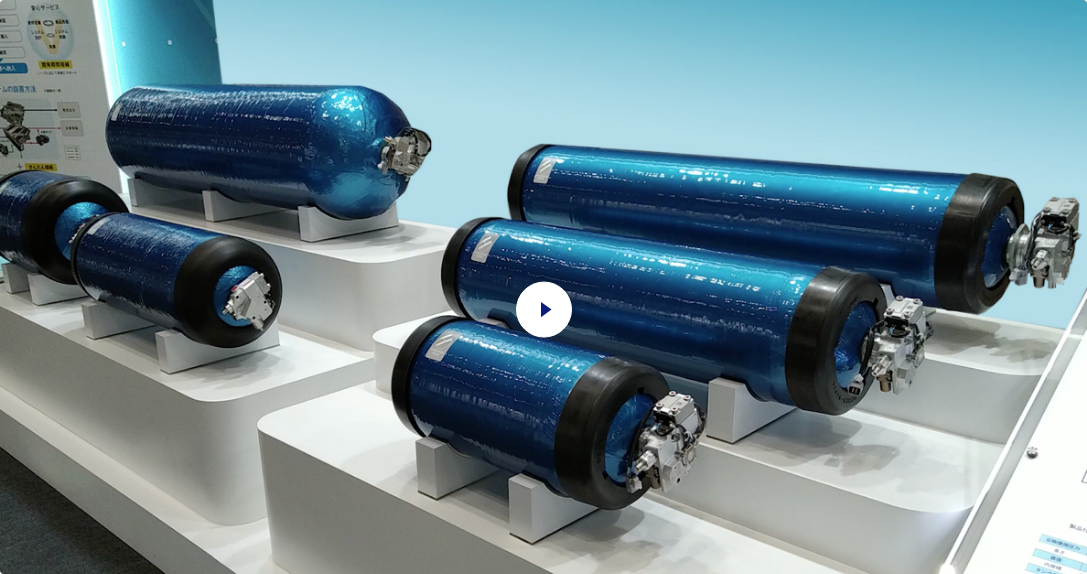

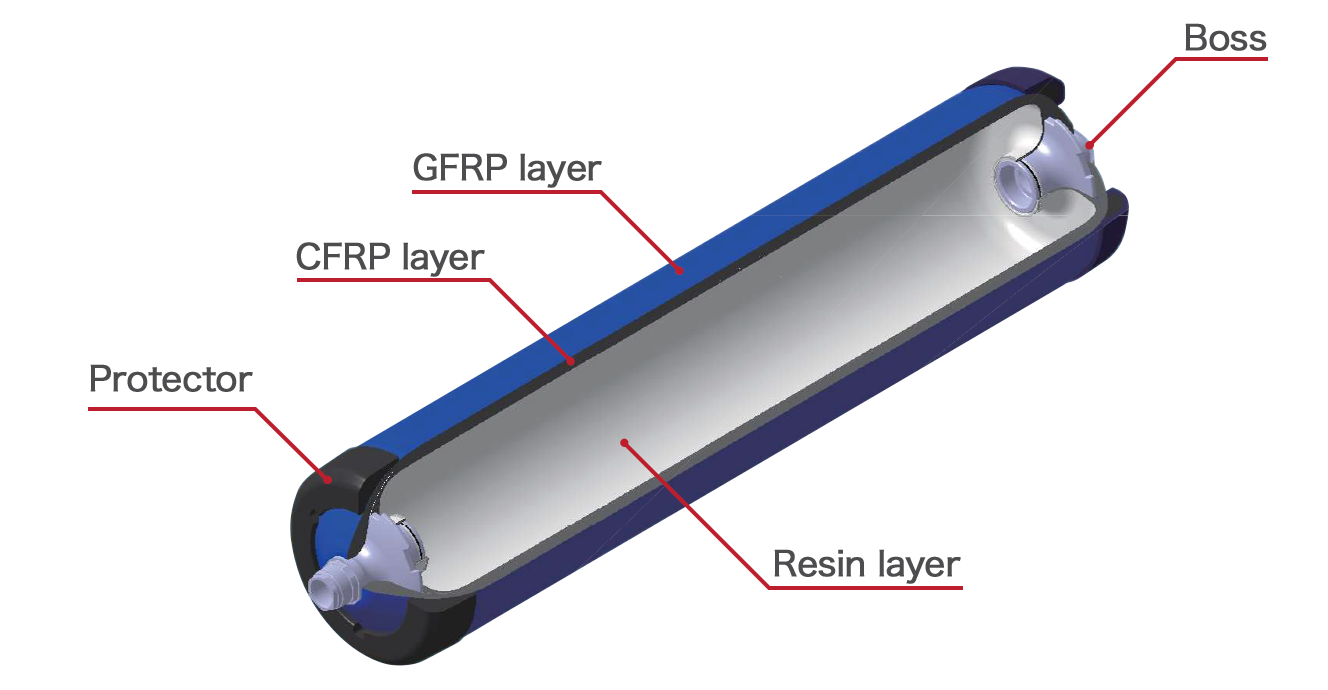

High-pressure hydrogen tank

Pioneer in building

70 MPa mass-produced tanks

Achieves world top-level 70 MPa

class hydrogen mounted mass

effectiveness *1 6.0 wt%

*1:Hydrogen mounted mass effectiveness (weight%)

= hydrogen mounted amount (kg)/tank mass (kg) × 100

Vehicle-mounted 70 MPa tanks have been produced since 2008, and more than 63,000 are used in the market.

The lineup ranges from low to high capacity tanks allowing combinations adapted to the intended use.

| G2-1 | G2-2 | G2-3 | G2L-1 | G2L-2 | G2XL-1 | ||

|---|---|---|---|---|---|---|---|

| Nominal use pressure | MPa | 70 | |||||

| Length | mm | 1,467 | 1,201 | 684 | 2,062 | 1,852 | 2,060 |

| Diameter | mm | 299 | 299 | 299 | 486 | 486 | 702 |

| Tank mass | kg | 43.0 | 36.7 | 22.6 | 134.2 | 121.5 | 243.8 |

| Hydrogen storage capacity@NWP | kg | 2.6 | 2.1 | 1.0 | 9.4 | 8.2 | 18.8 |

| Conformity Codes and Standards | GB/T 42612-2023*2 | Regulation on Safety of Containers annex11 | UN-R134 EU 2021/535 |

||||

| UN-R134, EU 2021/535 | UN-R134 EU 2021/535 |

||||||

*1 Note: Valves are not included in the above specifications. *2 Note: Expected to be certified 2024.

Do not hesitate to contact us for information on other tank sizes, mounting parts such as valves, bosses, and brackets, or help with setting up piping layouts or other systems.

High effective hydrogen concentration and unique robustness

Helps increase cruising range and prolonged use by allowing 98% of the hydrogen in the tank to be used up. Various customer uses and operating environments are taken into account to achieve high unique performance targets in addition to those required by laws and regulations. (E.g., low/high temperatures, collisions, or hydrogen charging.)

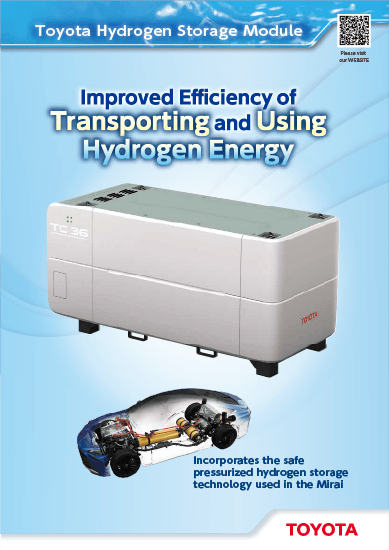

Hydrogen Storage Module

Basic performance

Four tanks using the same lightweight high-capacity resin found in the Mirai are connected in a single module. This allows for roughly four times the hydrogen transport efficiency as conventional metal racks when transported in combination with high-pressure 70 MPa storage technology, while decreasing transport weight.

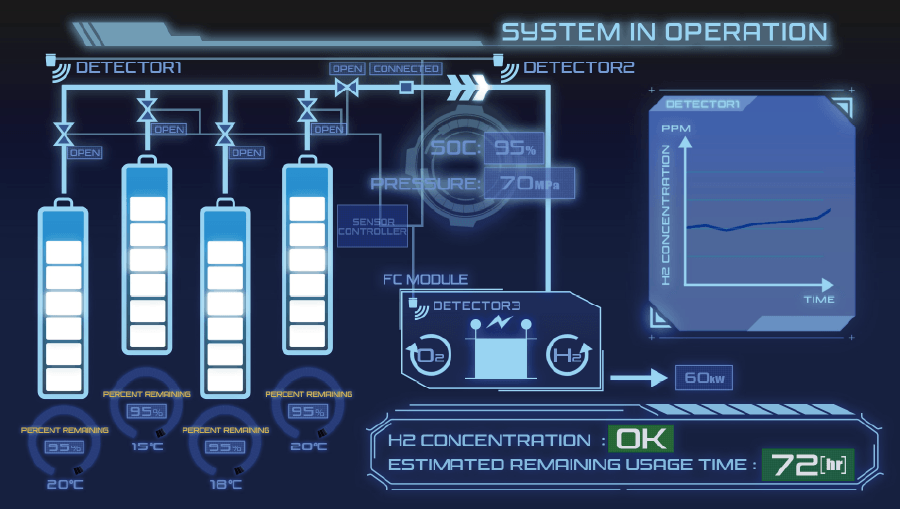

System monitoring*

Monitors remaining hydrogen and usage amounts. Centralized management of multiple modules through communication function.

Automatic Safety System*

Includes a safety system to detect any external vibrations or internal issues able to instantly stop hydrogen supply.

* Option package

Lineup

For Hydrogen Transportation

| Type | TC16 |

|---|---|

| Dimensions | L2,750×W1,250×H850 |

| Weight | Approx. 700 kg |

| Tank Type | G2L-2×2 tank |

| Hydrogen Capacity | Approx. 16 kg |

| Conformity Codes and Standards | Limited approval for Japanese regulation |

| Status | Demonstrating |

For Vehicle Installation

| Type | TC36V |

|---|---|

| Dimensions | L2,470×W550×H2,650 |

| Weight | Approx. 1,100 kg |

| Tank Type | G2L-1×4 tank |

| Hydrogen Capacity | Approx. 36 kg |

| Conformity Codes and Standards | Tank: UN-R134, EU 2021/535 Other components: To be approved by OEMs |

| Status | Demonstrating |